Let's kickstart the project TODAY!

Private label controllers & sensors

Making products that shape the future. All under your brand name.

With over 55+ years of expertise delivering built-to-last waveguide dehydrators and environmental control systems, many OEMs have chosen ETI Controls to build private label that carry their name and protect their reputation. Our team design, build, test, and support the electronics and controls behind the critical infrastructure you depend on.

Capabilities

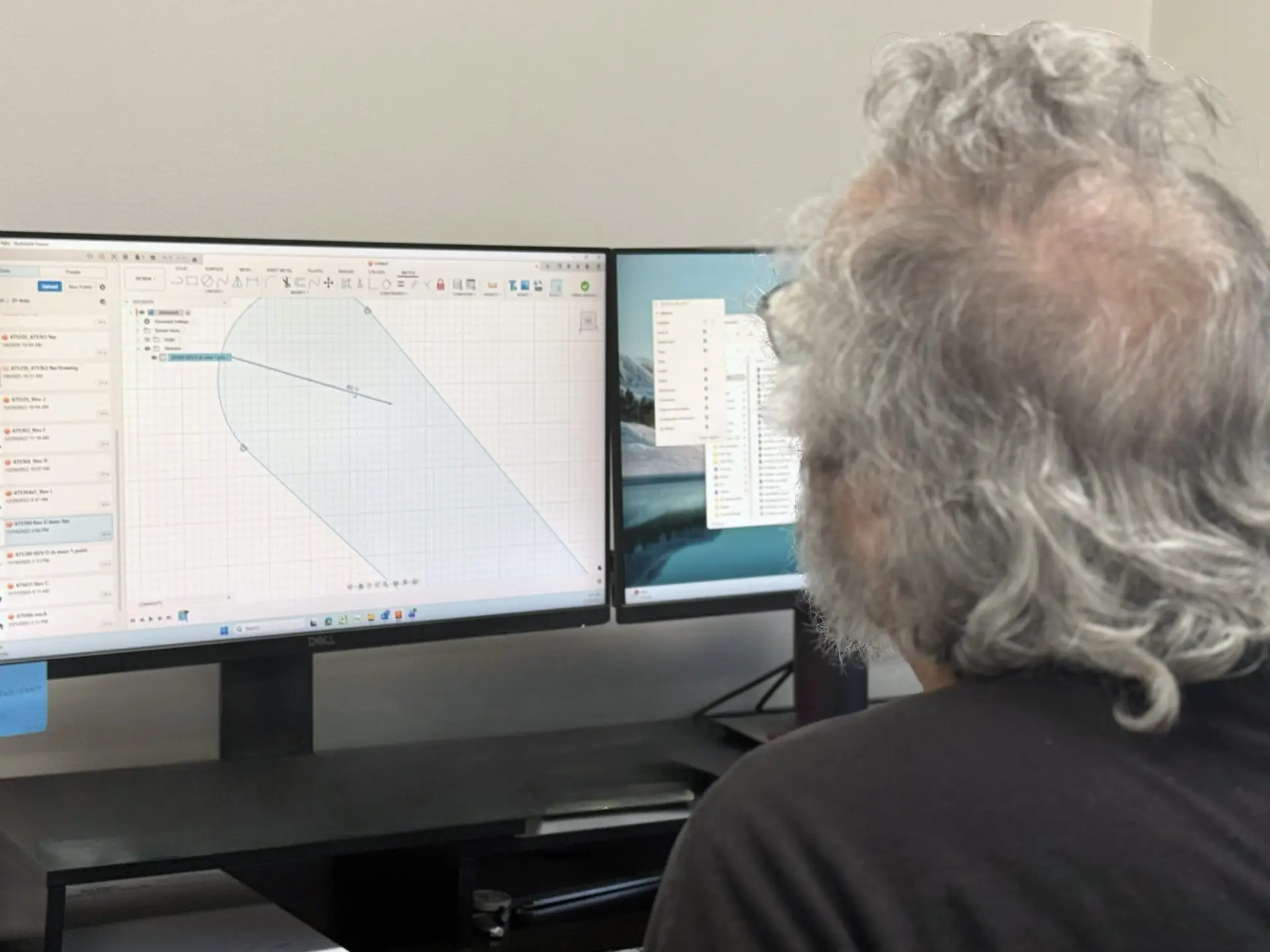

From vision to validated prototype

Whether you’re starting with a concept, a drawing, or an existing product, we help turn your idea into a manufacturable design:

- Requirements review and architecture

- Schematics and PCB layout

- Firmware and control logic

- Prototypes built for lab and field testing

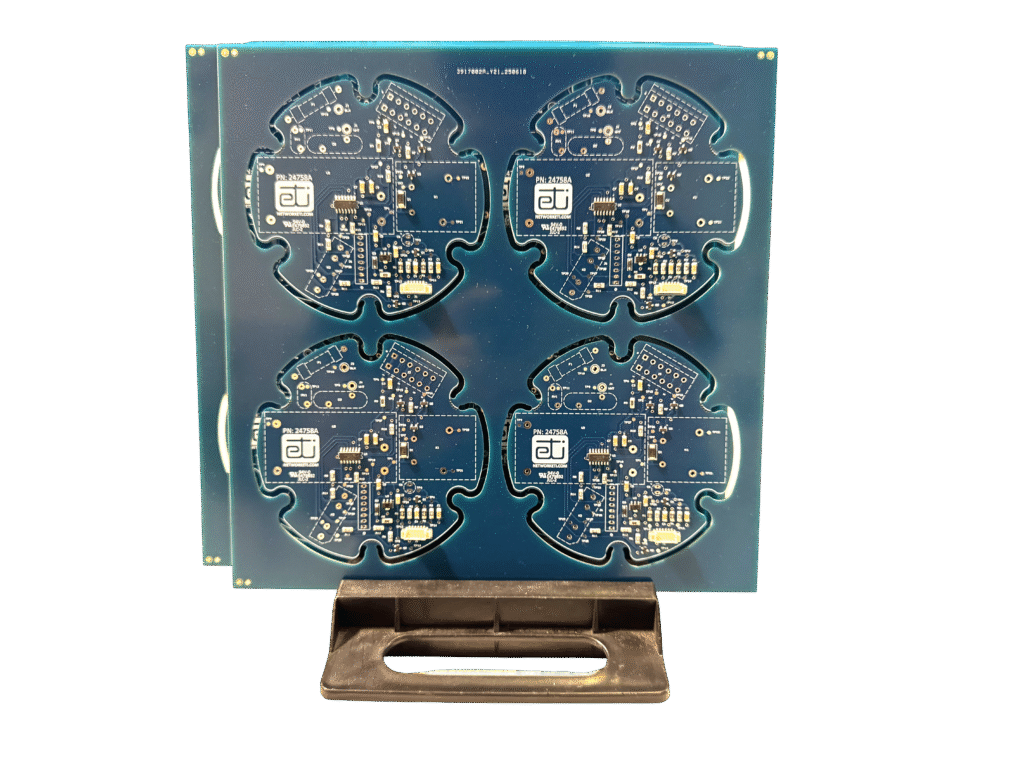

Production-ready builds

When you’re ready to scale, we move your design into controlled production:

- Custom enclosures and mechanical foundations to match your application and brand appearance

- PCB assembly and board-level testing

- System assembly and wiring

- Functional, environmental, and quality control checks on every unit

Flexible volumes

Not every program needs a huge first order. We support:

- Small-batch samples for qualification, certifications, and pilot programs

- Full production runs for established or growing product lines

Packaging and shipping

Your product ships under your brand, ready for your channels:

- Branded labels, documentation, and packaging

- Kitting and configuration to your spec

- Shipping to your distribution center or direct to your installation teams

Why private label ?

You may not want to build an entire manufacturing and engineering organization around one product line, but you still need it to perform as if you did.

![]() Full-scale production without full-scale overhead

Full-scale production without full-scale overhead

Gain design, test, and manufacturing capacity without adding factories, headcount, or capital equipment.

![]() One accountable partner instead of many

One accountable partner instead of many

When metal work, PCB boards, firmware, assembly, and test are split across multiple suppliers, delays, miscommunication, and finger-pointing are common. Private label with ETI Controls gives you a single team responsible for the entire system.

![]() Protect your schedule and your brand

Protect your schedule and your brand

Missed deadlines and inconsistent quality don’t just hurt a project; they hurt your reputation. A private-label partner that understands critical infrastructure helps you deliver reliably, not just “good enough.”

Why choose ETI Controls?

55+ years delivering critical systems

We’ve spent decades designing and building waveguide dehydrators and environmental control systems that run in demanding conditions around the world.

American-owned and American-built

ETI Controls is American-owned and American-built, and we’re proud to be an Indiana manufacturer with a clear mission: bring more manufacturing jobs back to the U.S. We operate two facilities in Indiana,South Bend and Westfield,as part of the ETI Network, giving us the capacity and flexibility to support OEM programs at scale. For us, “Indiana-built” means something: we don’t trade quality for short-term cost savings, we prioritize reliable U.S. sourcing, and we hold ourselves to the standard our neighbors and partners expect. Every product that leaves our floor has to live up to that promise: built to last, backed by real support, and trusted to perform in the field under your brand name.

Integrated capability: electronics, controls, and systems

We bring together PCB design and assembly, control logic, and system engineering. Mechanical, electrical, and software engineers work side by side so your product functions as a single, reliable system, not a collection of parts.

Quality built in, not bolted on

From engineering reviews and design-for-manufacturability to functional and environmental testing, we design for long-term reliability. Each unit is built to perform in the field, not just pass a bench test once.

Real support, real people

When you need help, you reach a person who understands the product—engineers and customer support who can answer questions, troubleshoot, and keep your system running. No runaround, no disappearing act.

Value beyond the transaction

We’re not here for a one-time build. We aim to be the long-term partner behind your brand:

- Supporting updates and enhancements

- Helping you plan next-generation products

- Keeping continuity when your customers depend on you

How the private label process works?

1. Discover

Share your vision, drawing, existing product, or challenges. We review requirements, performance targets, and timelines.

2. Design & prototype

Our engineering team refines the design, builds prototypes, and supports lab or field testing to validate performance.

3. Pre-production

We finalize documentation, fixtures, and test procedures. Small-batch builds confirm that the product is ready for scaled manufacturing.

4. Full production

Controlled builds, inspection, and functional testing make sure each unit meets your spec, every time.

5. Deliver & support

Products ship under your brand, packaged to your needs, with ongoing technical support and a partner who understands your install base.