Let's kickstart the project TODAY!

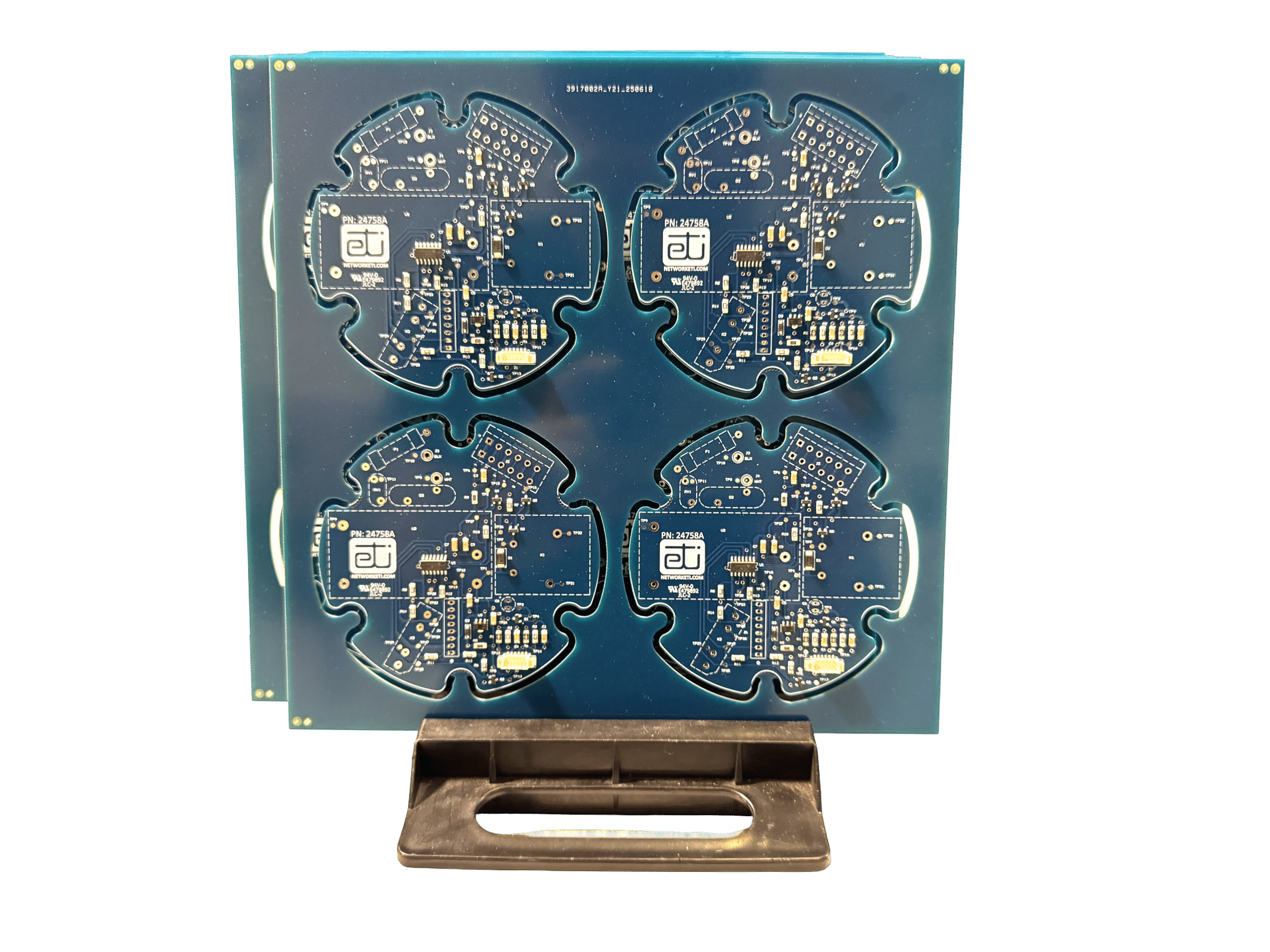

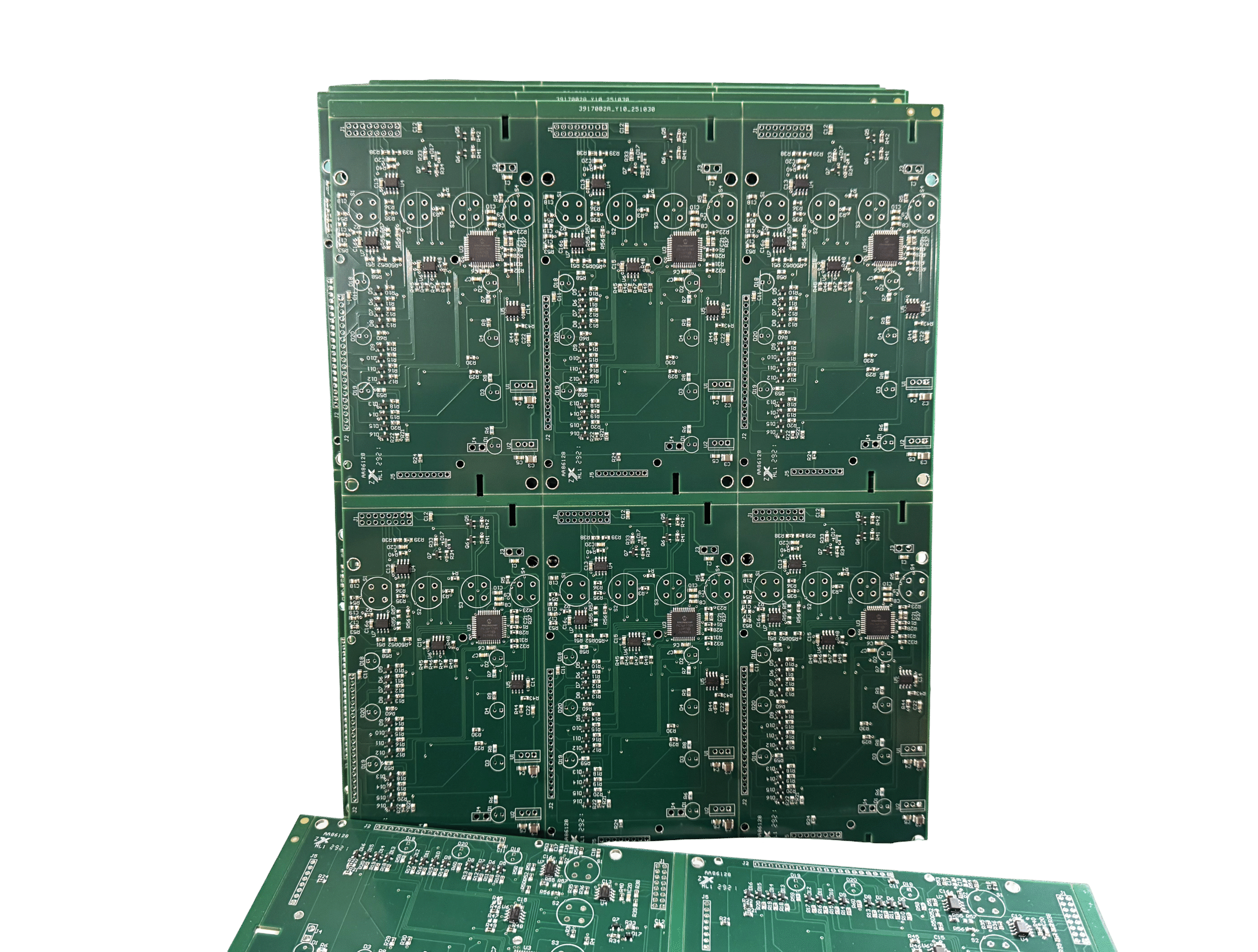

PCB Prototyping

Bring a finished layout or bring only a vision. We turn concepts into prototypes you can validate and scale. Prototyping is where great products begin. Every layout is engineered, checked, and optimized for cost, quality, and reliability.

You do not want frustration in the long run, do you?

90% of product failures and errors come from missing prototypes or inadequate testing. Under pressure, teams skip critical steps and carry the blame later. Sometimes a great idea appears overnight. You really commit to building it, and the next step is unclear. Prototyping is crucial and cannot be replaced by any shortcut. It turns risk into data and protects budgets, schedules, and reputations. We help turn your vision and drawings into reliable prototypes and production-ready boards.

Our production process

A successful prototype requires a comprehensive process and rigorous testing:

![]() Define requirements, constraints, environments, compliance needs, and acceptance criteria, then create a verification plan and risk register.

Define requirements, constraints, environments, compliance needs, and acceptance criteria, then create a verification plan and risk register.

![]() Review schematics and placement for signal integrity, power integrity, thermal margins, and EMI containment.

Review schematics and placement for signal integrity, power integrity, thermal margins, and EMI containment.

![]() Confirm stack up, impedance rules, creepage and clearance, return paths, decoupling strategy, footprints, and fabrication notes.

Confirm stack up, impedance rules, creepage and clearance, return paths, decoupling strategy, footprints, and fabrication notes.

![]() Plan manufacturability and test readiness with DFM, DFA, and DFT, including test points, fixtures, boundary scan, or in-circuit test.

Plan manufacturability and test readiness with DFM, DFA, and DFT, including test points, fixtures, boundary scan, or in-circuit test.

![]() Meet with the client to finalize scope, BOM alternates, risks, and approvals before any fabrication.

Meet with the client to finalize scope, BOM alternates, risks, and approvals before any fabrication.

![]() Build a controlled low-volume prototype and run AOI, flying probe, functional tests, power-on sequencing, and targeted thermal or stress evaluations.

Build a controlled low-volume prototype and run AOI, flying probe, functional tests, power-on sequencing, and targeted thermal or stress evaluations.

![]() Analyze yield and failure data, document changes and cost levers, and recommend reliability and manufacturability improvements.

Analyze yield and failure data, document changes and cost levers, and recommend reliability and manufacturability improvements.

![]() Prepare a pilot production plan with control documentation, acceptance criteria, and a clear path to scale.

Prepare a pilot production plan with control documentation, acceptance criteria, and a clear path to scale.

Why ETI Controls?

ETI has delivered reliable environmental control systems for 55 years. Our products support iconic sites like the Golden Dome. They serve government and military projects that demand consistency. ETI Controls extends that heritage to PCB design and assembly. Our team spans electrical, mechanical, firmware, and test engineering. We prototype in low volumes and prepare for dependable production. We build in Indiana to strengthen supply chains and protect IP. We support private-label products and long-term lifecycle needs. Your success is measured by performance in the field, not speed.